CliqStudios Kitchen Cabinet Finishes

Color is the first thing everyone notices in a kitchen. Apart from the cabinet layout and storage, cabinet finishes are the next biggest remodeling choice on everyone’s mind. Cabinet finishes can quickly determine whether a design is inviting or off-putting.

Carefully select your finishes and make sure that the cabinet line offers the best options in terms of budget, construction, cabinet storage and finishes to meet all your needs. This will help you make the most educated design decision and will impact your long-term happiness.

Explore our most popular cabinet finishes broken down by cabinet line and learn what to consider when choosing your finishes.

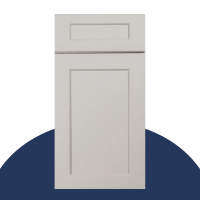

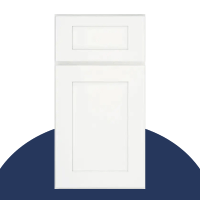

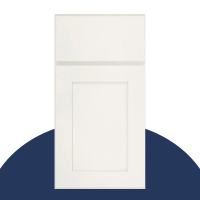

White Cabinets

CliqStudios white cabinets are offered in all our lines including Craftsman, Signature Plus, Mercury and RTA. White is the perfect finish to create the illusion of a larger space while lightening the color scheme.

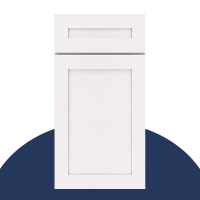

Sea Salt

Sea Salt paint is a fresh white that creates an airy and bright look.

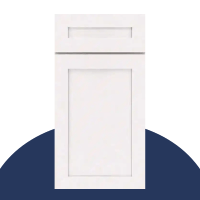

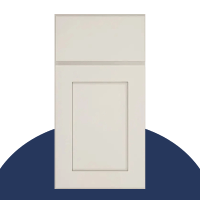

Divinity

Divinity is a warm white paint color that provides an inviting look.

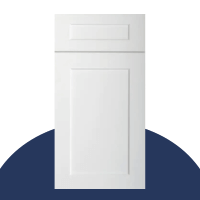

Lily

Lily is a classic, soft white paint that brightens up any room.

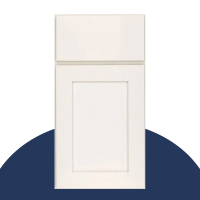

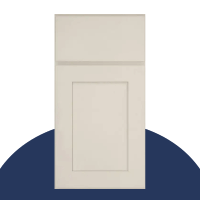

Chalk

Chalk is a classic, soft white paint that brightens up any room.

Pearl

Pearl is a true white color that adds a refreshing, clean look and feel to a space.

Gallery Inspiration for White Cabinets

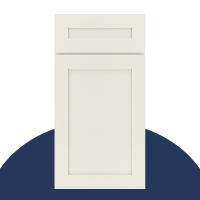

Cream Cabinets

CliqStudios cream cabinets are offered in our Craftsman, Signature Plus and RTA cabinet lines. Cream is a beautiful bright finish with a warmer undertone that creates a more traditional feel.

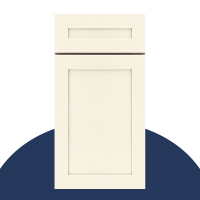

White Icing

White Icing is a soft off-white paint color that creates a cozy, charming look.

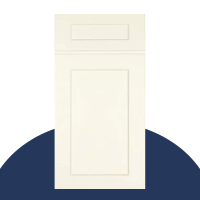

Irish Creme

Irish Crème is a soft beige paint color that creates a calm, relaxed look.

Silk

Silk is a light cream paint that adds a bright and cozy look to any space.

Ivory

Ivory is a soft, creamy white that adds an inviting, welcoming feel to your space.

Gallery Inspiration for Cream Cabinets

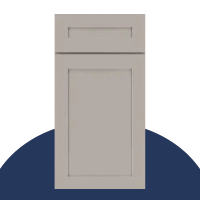

Mushroom Cabinets

CliqStudios mushroom cabinets are offered in our Craftsman, Signature Plus and Mercury cabinet lines. Mushroom is the subtle finish that creates a lived-in space that feels warm and inviting.

Chai Latte

Chai Latte is a muted taupe paint that provides a calming and classic look.

Mist

Mist is a soft beige paint that adds light and warmth to any space.

Pebble

Pebble is a light taupe paint that adds contrast to any space while maintaining a neutral palette.

Gallery Inspiration for Mushroom Cabinets

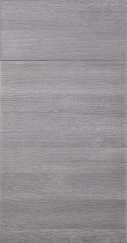

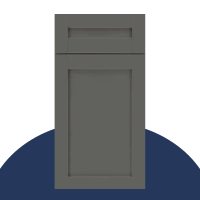

Gray Cabinets

CliqStudios gray cabinets are offered in all our lines including Craftsman, Signature Plus, Mercury and RTA. Gray is a modern finish that provides a sleek and updated look for both kitchens and bathrooms.

Gallery Inspiration for Gray Cabinets

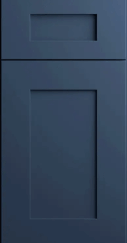

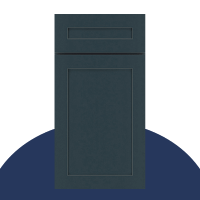

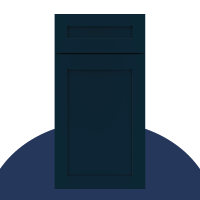

Blue Cabinets

CliqStudios blue cabinets are offered in every line including Craftsman, Signature Plus, Mercury and RTA. Blue is a stunning finish that adds a versatile pop of color and style to any remodel.

Gallery Inspiration for Blue Cabinets

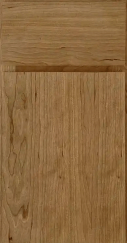

Light Wood Tone Cabinets

CliqStudios light wood tone cabinets are offered in Signature Plus and Craftsman cabinet lines. Light wood finishes are perfect for showing off wood grain patterns in organic and rustic designs.

Natural

Natural stain is a neutral wash of color to showcase the natural beauty of the wood grain.

Gallery Inspiration for Light Wood Tone Cabinets

Medium Wood Tone Cabinets

CliqStudios medium-tone wood cabinets are offered in our Craftsman, Signature Plus and RTA cabinet lines. Medium wood finishes are a more subtle wash of color, giving you more versatility in your wood finish and color scheme.

Fossil

Fossil is a light muted brown stain with subtle gray undertones that provides a more natural look.

Gallery Inspiration for Medium Tone Cabinets

Dark Wood Tone Cabinets

CliqStudios dark wood cabinets are offered in all our lines including Craftsman, Signature Plus, Mercury and RTA. Dark wood finishes are a sleek and modern choice that allows you to warm up your space with wood tones.

Gallery Inspiration for Dark Wood Tone Cabinets

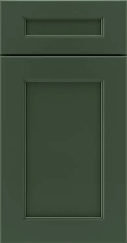

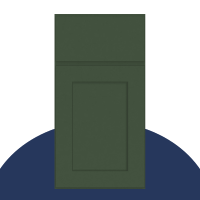

Green Cabinets

CliqStudios green cabinets are offered in our Craftsman and Signature Plus cabinet lines. Green is great for historic, moody and edgy designs in any part of the home.

Eucalyptus

Eucalyptus is a cool, forest green paint that creates a calming and contemporary look.

Gallery Inspiration for Green Cabinets

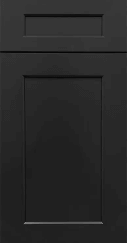

Black Cabinets

CliqStudios black cabinets are offered in our Craftsman, Signature Plus and RTA cabinet lines. Black is an elegant finish that elevates any design with dramatic contrast.

Carriage Black

Carriage Black is a classic rich black paint that creates an elegant look.

Twighlight

Twighlight is a jet-black paint that adds drama and definition to any design.

Gallery Inspiration for Black Cabinets

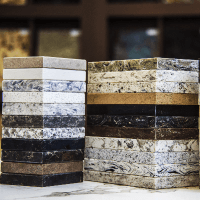

What to Consider When Choosing a Cabinet Finish

Kitchen Color Scheme & Trends

Choosing your color scheme involves a lot of decisions. Do you go with current design trends, or do you choose a timeless kitchen design? Think about what will make you happiest in the long term. Sometimes a punch of vibrant color is the right decision. However, if you notice yourself getting sick of trendy decor and colors after a few years, it might be best to choose timeless kitchen color palettes.

Look at inspirational photos on Pinterest and Houzz to see what you are most drawn to. Does the dark and moody aesthetic match your personality, or do you need light and bright colors to feel comfortable? The design industry is constantly evolving and changing, so it’s easy to get drawn into new looks. However, it’s best to be conservative with more expensive design choices and decorate with bolder colors and patterns. This gives you the versatility to change things when you get bored.

How Busy is Your Home?

It’s normal to see finish selections change based on lifestyle. A home with kids or pets, for instance, will look a lot different than one without. In a home with children, finishes should be chosen based on durability, scratch-resistance, and how well they can cover up a mess while still looking great.

Easily add interest to your kitchen design while disguising the mess with a two-tone cabinet design. Darker cabinets on the kitchen island, or all the base cabinets will be both functional and beautiful. When the inevitable scratch or knick happens, it will be much less visible and easier to touch up.

How Often Do You Clean Your Cabinets?

After a few weeks of use, you will start to notice dirt and grim building up on your cabinets. The best practice is to wipe your new cabinets down weekly to avoid build-up. But some homeowners clean less than others.

When residue and grease build up on cabinets, it’s easier to see on lighter colors. If you commit to cleaning your cabinets more often, then go for bright white shaker cabinets. But if you don’t want to clean that often, wood tones and medium to dark paint colors are your best bet.

Cleaning your new kitchen cabinets is simple. Stay away from any cleaning solutions with heavy chemicals, silicones or abrasives. Use a non-colored microfiber towel with some water and a gentle cleanser to wipe down all cabinet surfaces. With regular cleaning, your kitchen will look brand new for years.

What to Expect with Paint

Paint finishes are a great choice for many different reasons. With so many colors available in today's market, there is virtually no limit to what style or color palette you’re dreaming of. The sheer versatility to create anything from modern coastal to a craftsman-style kitchen is amazing.

With all that said, paint does have a few drawbacks. Although it’s a baked-on factory finish, no finish is indestructible. Especially when it comes to children and pets. Any paint touch-ups will likely show since you will be using new paint on an older finish. If you foresee kids hitting the cabinets with toys or dogs jumping up on cabinets, consider a different finish for the lower cabinets.

It’s also normal to see hairline cracks in the paint along the corner joints. This is normal because wood products are always expanding and contracting with temperature changes. These cracks will be more visible with painted finishes than stained finishes.

What to Expect with Stains

Stained finishes are popular because they bring warmth and character to any room. Like paint, there are many colors to choose from and wood species. All wood species have different grain patterns and will age differently as time passes.

If you love light wood finishes, do your due diligence to see how your selected wood species will age. Some get darker over time and some even change color, like cherry, settling into a pinkish-red hue. Stains are a great option for a busier household or for someone who has pets and kids. With varying wood grains and visual texture, it’s easier to cover up scratches and knicks.

Explore CliqStudios kitchen cabinets to find your perfect color palette today!

FAQs

Are white kitchen cabinets still popular in 2024?

Yes, white kitchen cabinets are still a popular choice in 2024. This style and color combination is timeless because of its simplicity. White is a great foundation for many different types of kitchen designs and color palettes, not to mention it brightens any room. Pair white shaker cabinets easily with light wood finishes for a modern organic kitchen design, navy blue for a coastal style or black for a chic transitional design. This door style and finish combination is a timeless choice that will be popular for years to come.

Is a paint or stain finish better for kitchen cabinets?

Paint and stains are both excellent finishes for kitchen cabinets. The choice comes down to you and how your family functions. Painted finishes are great for homeowners who entertain and are easier on cabinets. It allows you to achieve virtually any color palette and provides a high-end look. The downside is that paint can be hard to repair. Stained finishes are beautiful and provide a variety of different looks as well. These finishes create a warm and down-to-earth look while also disguising any scratches and knicks. CliqStudios offers two free color chips, so order your favorite finishes and test them out. Consider your needs and what would benefit you most before making your final choice.

How often should I clean my kitchen cabinets?

As a best practice, we recommend cleaning your cabinets with a wet cloth at least once a week. About once every month, use a gentle, non-abrasive cleaner with water on a non-colored microfiber to remove any dirt and grime. Grease, oil and dust can accumulate on cabinets over time and some finishes are more forgiving than others. The best way to prevent damage to your cabinet finish is by cleaning up messes right after they occur. This will keep your cabinets looking shiny and new for years to come.