How To Begin Your Kitchen Remodel Journey

You’ve finally decided it’s time to update your kitchen. Those crooked drawers and doors aren’t getting any easier to open, and that awkward corner needs a Lazy Susan. So, how do you start the process of choosing the right kitchen cabinets for your new kitchen?

There are a few basic steps you should take as you begin your journey to a more organized and efficient kitchen. Most importantly, you should realize that renovating or remodeling a kitchen is a big commitment. You’ll need to carefully plan and budget for what you want versus what you really need and can afford.

List Your Dream Kitchen Items

If you’ve been gazing dreamily at newly remodeled kitchens online, you probably have your ideal kitchen in mind. This is the time to go wild and make a list of everything your current kitchen lacks and all the items you want in your new one.

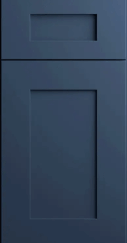

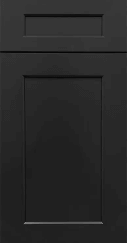

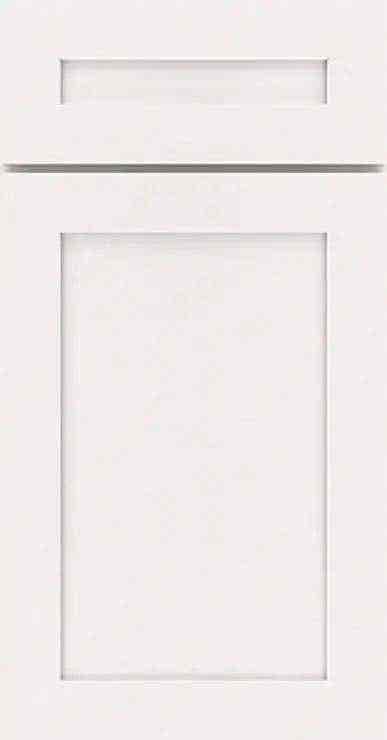

In your online search you might have spied the perfect Blue kitchen cabinets, or maybe the perfect inset white Shaker cabinet drawers with glistening gold hardware. Perhaps an island that seats four, with a built-in beverage cooler as well. Your stunning new kitchen cabinets will include mullion glass-front doors surrounding that high-end professional chef’s range.

The “dream phase” is essential to starting a remodel, because it helps you create goals and set expectations for your project. This is the time to pin down the things your new kitchen needs over the luxury items you want. (You will narrow these down even further when you start planning your budget.) Do you want improved functionality for the space you have? Is a better-organized kitchen important? Focusing on what you need to improve your situation will better prepare you for the next steps of your kitchen remodel. .

Set Your Budget

Knowledge is power. You can confidently set a budget only after you’ve shopped around and compared all the product options out there. Your budget depends on what you have, what you can comfortably spend, and the financing options available to you.

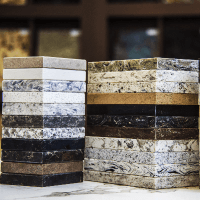

According to HomeAdvisor, as of 2020 the average cost of a kitchen remodel is $25,257, or $150 per square foot. Most homeowners spend between $13,271 and $37,512, or $75 to $250 per square foot. Generally, kitchen cabinets make up about 29% of the remodeling budget. On average, professional kitchen designers charge between $100 to $200 per hour for their services. This includes 3D renderings, material and color selection, start-to-finish support, and project management.

A well-planned budget helps you prioritize where you want to invest your dollars and where you can reduce costs. Your budget can also be impacted by whether you DIY or hire professional installers to do the work.

Pick Your Cabinet Line, Choose Your Journey

When the exploration process starts and it’s time to decide on a cabinet line, how do you choose? With three cabinet lines, Ready-to-Assemble (RTA), Signature Plus, and Craftsman, you have plenty of options. Think of these lines as the most affordable, most popular, and most customizable. Each is high-quality, but offers various finishes and accessories at multiple price points to fit any style and budget.

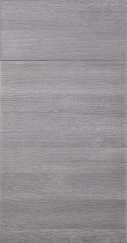

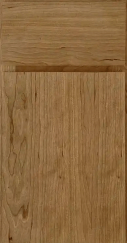

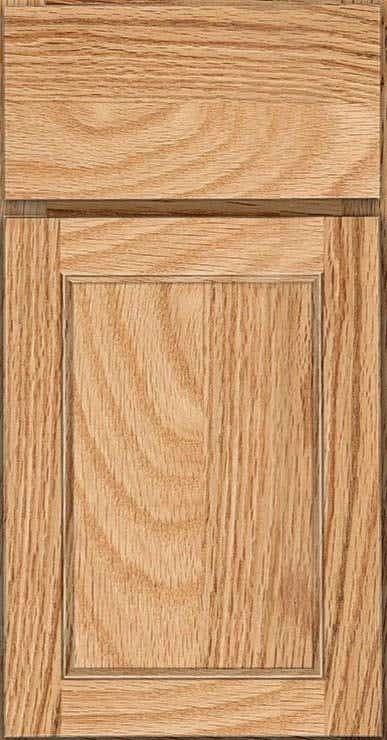

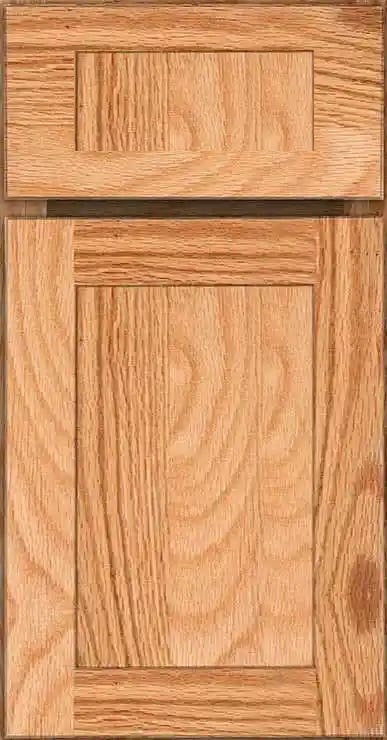

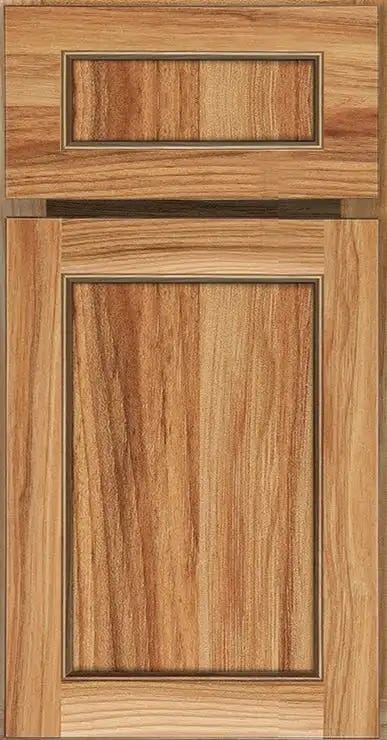

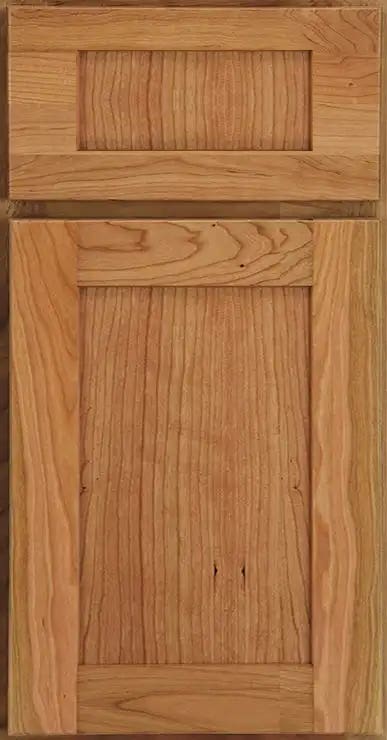

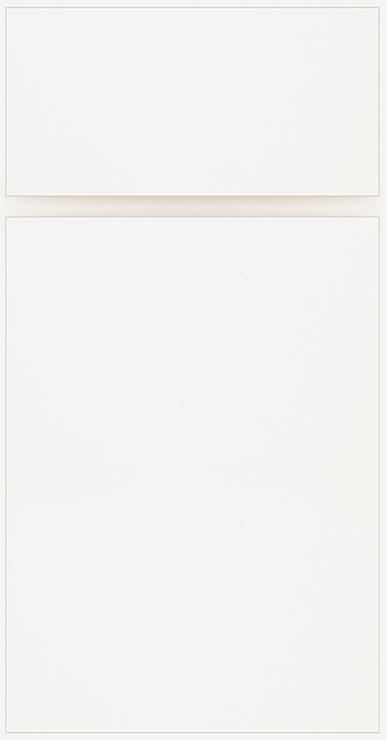

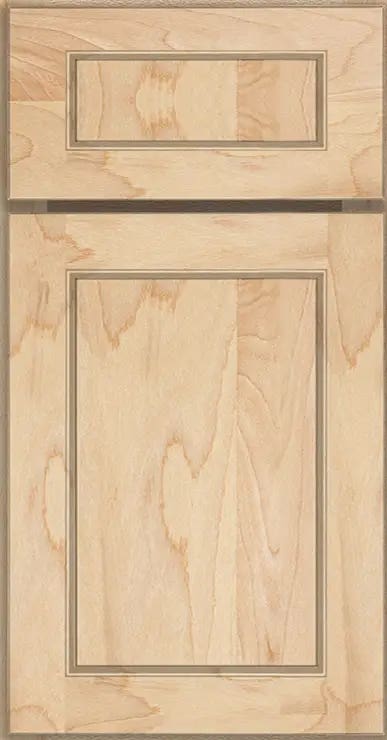

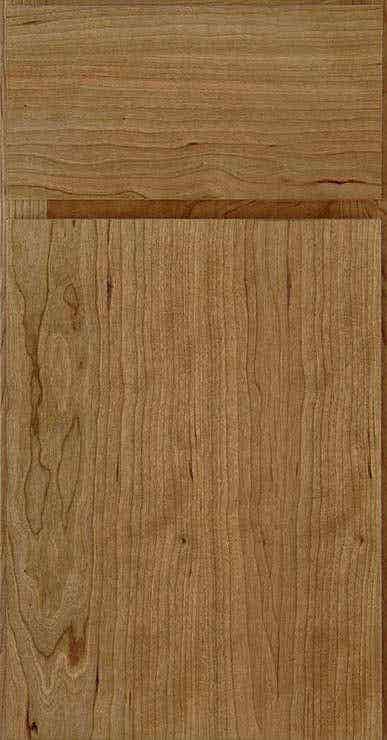

Our RTA, or ready to assemble cabinets line is our most affordable line, featuring all-plywood construction and top door styles and finishes. This line offers standard wall cabinet and base cabinet sizes, some accessories, and will ship flat-packed. If DIY assembly isn’t your style, you can hire a professional to assemble them and complete cabinet installation for you. RTA also now offers some door styles in frameless construction.

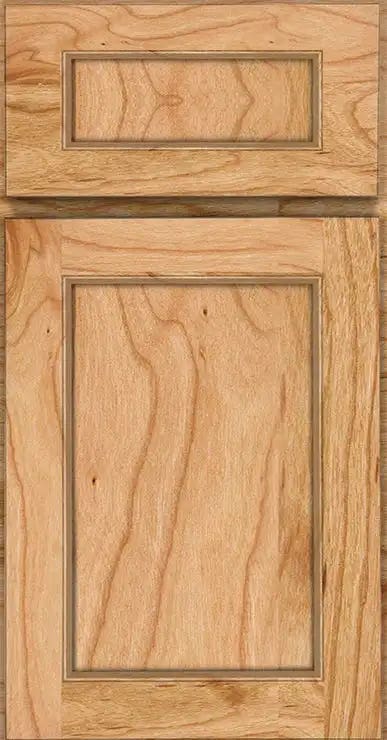

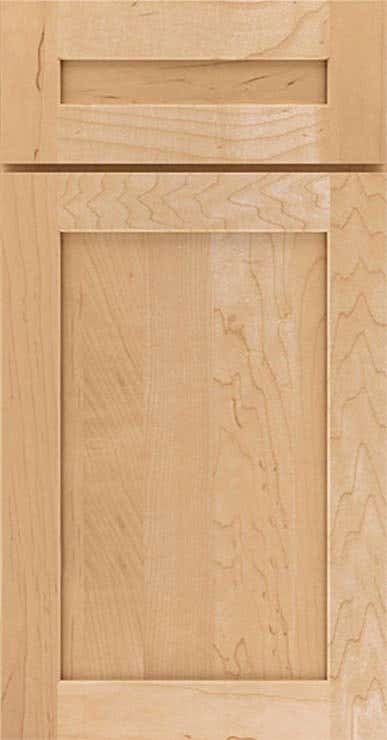

Signature Plus is our most popular cabinet line. You will see a wide array of modifications, construction options, and cabinet accessories in this line, as well as a larger variety of door styles and finishes. Since there are many more options in this line to customize your kitchen, the price point will be higher than RTA. Ordering Signature Plus’s semi-custom cabinets means your order will arrive fully assembled and ready to install.

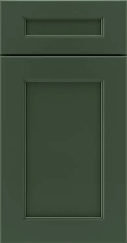

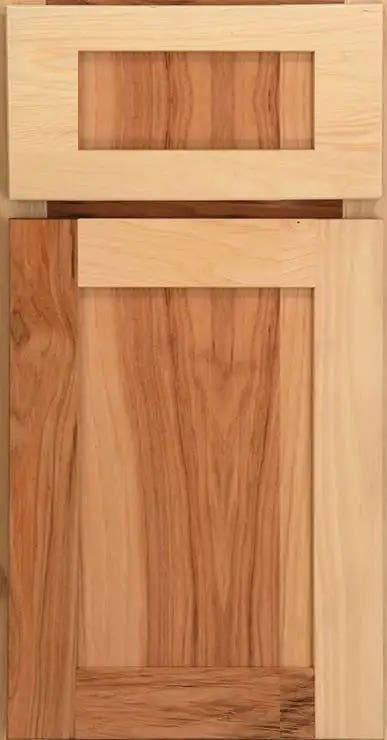

Craftsman line features are our most customizable cabinets. Like Signature Plus, this line offers many construction styles, and a much more expansive offering of door styles including inset cabinets, finishes, accessories, wood species and custom options. Craftsman offers 100s of style and colors combination and nearly limitless design options.

Keep in mind that the cabinets you choose will determine your journey. If you would like a DIY experience where you can shop on your own, then RTA cabinetry is likely the best choice for you. However, if you would like a wide selection of colors and styles, designer assistance, and assembled cabinets, then we recommend starting with our custom lines, Signature Plus and the Craftsman.

Connect With A Professional Kitchen Designer

Next up you’ll need to measure your space or hire a professional to help. You can do this either before or after you meet with your designer. Regardless, a professional will make sure your measurements are accurate so that your kitchen design will accommodate new cabinets, appliances, crown molding, and other finishing touches you have in mind.

Working with an experienced kitchen designer is the smoothest path to a successful remodel or renovation and necessary when working with Signature Plus or Craftsman cabinet lines. From choosing cabinet doors, cabinet placement, choosing between islands or peninsulas, storage solutions, and what to do with those hard-to-reach corners, a designer offers the expertise to make your dream kitchen a reality. Additionally, our RTA cabinets are the only line shoppable on our website, so if you select our Signature Plus or Craftsman line, you will need designer expertise.

At CliqStudios, we’ve been a digital company from the very beginning, and we’ve been using online virtual design consultations for a while now. Our kitchen designers are equipped with webcams and screen-sharing capabilities to help customers achieve their kitchen remodel and renovation goals for the best results in the custom cabinet industry. The virtual design process is much more efficient than email and text consultations, providing you with the best kitchen design for your unique situation.

Be Open to Compromises and Expect Delays

A kitchen remodel, or any home renovation for that matter, is a process that usually requires compromises. It’s a balance between creating your ultimate dream kitchen and one that fits within your budget, but still checks all the right boxes.

Unexpected delays can pop up anytime, so you should be mentally prepared to deal with them. Can you live with extended construction periods to wait for the items you want? If not, you may have to settle for alternatives to get the job done sooner.

Kitchen Cabinets from Start to Finish

There’s no doubt that a kitchen remodel or renovation is a major undertaking. There’s a lot to ponder and consider, but when it comes to choosing the right kitchen cabinets and storage solutions for the heart of your home, CliqStudios makes the process easy. From initial design, cabinet style choices, selection, and delivery, we’re with you every step of the way. And remember — our kitchen designers work with you free of charge!

Browse our wide selection of kitchen cabinets, from ready-to-assemble cabinets to custom cabinets including Shaker, Slab, Decorative and Inset styles. Begin your kitchen remodel journey with a free design consultation.