Cabinet Components

A kitchen cabinet is a simple wood box. However, there are a number of cabinet components that go into creating a cabinet. Kitchen cabinet parts include face frames, doors, hinges and more. The quality of these components varies widely depending on the manufacturer. Assembly methods also vary, which can affect the quality of the cabinet. Learn what makes a quality cabinet, with a breakdown of the basic parts below.

Learn About CliqStudios Cabinet Construction

What Are the Parts of a Kitchen Cabinet?

Cabinet Face Frame

Although some cabinets are frameless, the most popular American semi-custom cabinet has a cabinet face frame. They are known for providing stability during shipping and installation; however, frameless cabinets are just as stable and durable once installed.

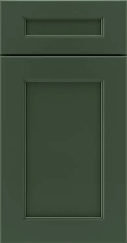

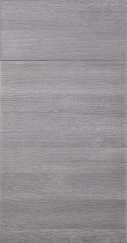

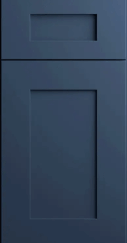

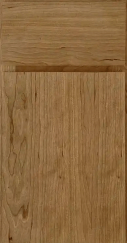

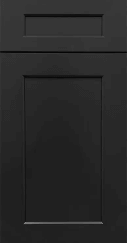

Doors and Drawer Fronts

Doors and drawer fronts are one of the most prominent cabinet parts. Choosing a cabinet door style and color is one of the most exciting parts of the design process. CliqStudios doors and drawer fronts are made with solid hardwood or high-density furniture board (HDF). The center panel material will vary depending on the style and finish of the door. CliqStudios’ furniture quality wood stains and enamel paints are hand-applied in a 11-step process with a clear, durable topcoat baked on for a smooth, lustrous finish.

Hinges

Hinges are an important kitchen cabinet part, and their quality varies greatly. It’s important to choose cabinets with high-quality hinges, because they will be opened and closed thousands of times. All hinges on CliqStudios cabinets are steel, soft-close, concealed and have six-way adjustability.

Drawer Glides

A typical silverware drawer contains 20 pounds of flatware. That means having hardwood drawer boxes with glides that can hold at least 75 pounds is best. Soft-close, steel, undermount glides come standard on all CliqStudios cabinetry.

Drawer Box

The standard for quality in American cabinetry calls for a drawer box with solid hardwood sides and back at least ½-inch thick, built with dovetail joints. The bottom should be fully captured, meaning it is set in grooves on all four sides.

Plastic and metal are common drawer box materials, but they are not as durable as wood. Drawer-box material and joint construction is an important consideration, because the joints and drawer bottoms are among the first things to fail in low-end kitchen cabinetry.

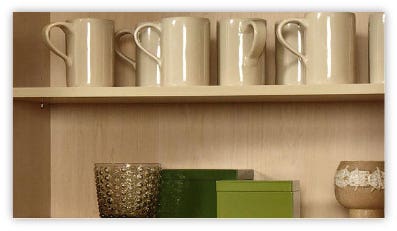

Interior Finish Material

Kitchen cabinet interior and shelf surfaces should be non-porous so they can easily wipe clean. This helps extend the life of the cabinets without interiors staining, bubbling or showing wear. Standard interior surface materials include melamine and laminates. They are generally a light natural maple wood-tone color to make the contents easy to see. A wood veneer interior or shelf surface will absorb moisture, stain easily and trap soil in the grain of the wood. Rather than a laminate interior, glass-front cabinets often match the interior to the exterior finish.

Cabinet Shelves

Plywood and furniture board are the most common materials for cabinet shelves. Because this cabinet component bears weight, strength is a primary consideration. Base cabinets have full-depth or half-depth shelving. Cabinet shelving can be ½-inch thick, but ¾-inch is preferable.

Learn more about CliqStudios cabinet construction today!

Frequently Asked Questions

What are the components of a cabinet?

There are several components that make up a cabinet. The main components of a cabinet include the face frame, doors and drawer fronts, cabinet hinges, drawer glides, drawer boxes, cabinet shelves, and interior finishes. However, some cabinets are considered frameless meaning there is no face frame, and cabinet construction options will vary based on the line chosen. Most cabinet lines allow you to choose kitchen cabinet components like whether you prefer furniture board or all-plywood construction.

What are the different types of cabinet materials?

Cabinets can be made of a few materials that can be separated into two categories: wood and wood-like materials. Maple, Birch, and Oak variations are just a few of the wood types typically involved in cabinet construction. Other materials such as plywood, particleboard, and veneer. To learn more about the specific cabinet materials that CliqStudios uses to construct our cabinets, check out this article or talk with your CliqStudios designer!

What is the structure of a cabinet?

Cabinet construction typically includes a few main materials. The cabinet box is the outer shell which may or may not have a face frame on the front depending on your preferred cabinet style. Next you will find drawer boxes and glides, doors and drawer fronts, and cabinet hinges. Other kitchen cabinet parts commonly include shelving and laminated interiors. Typically, the highest quality cabinets have a factory finish whether paint or stain, and solid wood drawer boxes with dovetail construction.