Cabinet Materials: Plywood, MDF and More

CliqStudios Cabinet Materials

Cabinet materials play a large role in the life span and beauty of your kitchen. Learning about CliqStudios cabinet materials will help you choose the best cabinet line for you. Building cabinets with a combination of wood-based materials allows us to offer a wide range of styles, durability, and prices. CliqStudios cabinet lines are made of the following materials:

- Hardwood

- Plywood

- Furniture Board (MDF)

- High-Density Fiberboard (HDF)

- Wood Veneer

Of course, box materials are just the starting point of a cabinet. High-quality cabinets will also have features like soft-close hinges, storage options, and warranties.

Hardwood

Hardwood is durable, resilient, and easy to repair.

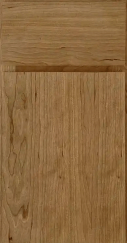

Solid hardwood is a natural wood product. Each piece of wood has unique color, texture, and grain patterns. This often includes mineral streaks and knots. The natural variations in this cabinet material add to the distinctive appeal and beauty of hardwood cabinets.

You can sand and refinish scratches, dents, stains, or water marks in hardwood to increase its lifespan. Hardwood is typically used in cabinet face frames and door and drawer fronts. Hardwood is rarely if ever, used to build the entire cabinet. This is because of high wood prices and weight. Another reason is because wood can warp when it contracts and expands with temperature and humidity changes. Therefore, other engineered woods are often used for painted doors and drawer fronts of hardwood cabinets.

Plywood

Plywood holds screws securely, resists moisture, and is resilient to dings, dents, and sagging.

It is made by layering wood at alternating right angles, and binding them together with glue, heat and pressure. Rigid and stable, plywood has the highest strength-to-weight ratio of all cabinet building materials. Consumer Reports recommends plywood as the premium quality option for cabinets. Plywood cabinets hold screws more securely and resists moisture better than alternative cabinet materials. It is resilient against blow-outs, dings, dents, and sagging, making it a great choice for cabinet sides, backs, shelves, and drawer bottoms.

Furniture Board (MDF)

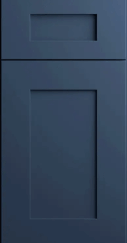

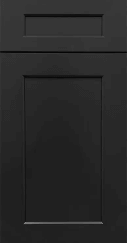

MDF is a good choice for painted surfaces, like doors.

This product is attractive to consumers as a more affordable alternative to plywood.It is a composite cabinet material made from recycled fibers, resin, and wax. This engineered wood product is pressed together under high pressure, making MDF a strong option. MDF resists expansion from temperature changes and has a smooth surface. This makes it a good choice for painted surfaces like the center panels on painted doors.

High-Density Fiberboard (HDF)

HDF is a great choice for cabinet doors because of its smooth surface.

Made from soft and hardwood fibers and formed with resins under high heat and pressure, high-density fiberboard is a great cabinet material. It's similar to MDF in the fact that it is made from fibers, resin, and wax, but offers even more strength and water resistance. The main difference is that it is even more dense than MDF, making it another great material for cabinet doors and panels.

Wood Veneer

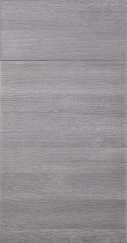

Wood veneer is a finish material made of solid hardwood.

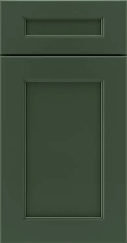

Veneer is made by peeling a thin layer of solid hardwood from a log. They are usually less than 2mm thick and are typically glued and pressed to other cabinet materials to produce flat panels. Unlike the materials above, hardwood veneer should be understood as a finish material, because it is not used to construct the actual cabinet box or frame. In cabinets, hardwood veneer is used to finish the large panels of the cabinet sides. It is also used in the flat center panels of Shaker and Mission style doors. In these applications, veneer is preferred for its stability and light-weight application.

CliqStudios Cabinet Materials

CliqStudios cabinets are made with a combination of these cabinet materials to create the highest quality products at the best prices. No matter your price range, construction preference, or style, we have the perfect cabinets to fit your new kitchen

Frequently Asked Questions (FAQs)

Where do I buy cabinet refacing materials? Does Cliqstudios sell refacing material?

Cabinet refacing materials can be purchased through any big-box store if you like DIY. If you prefer to hire a professional, search online for cabinet refacing companies near you. CliqStudios does not currently sell refacing kitchen cabinet materials.

What is the best material for cabinets?

In terms of cabinet construction and a long lifespan, plywood has been known to be incredibly strong, stable, and moisture resistant. This cabinet material is a great choice and will benefit kitchen cabinets and bathroom cabinets with its durability.

What material are kitchen cabinets made of?

Depending on the brand you choose, kitchen cabinets will be made from a range of materials. All brands will offer some variation of MDF and all-plywood construction or a mixture of the two. Cabinet doors however, will come in either hardwood, MDF with a veneer, or HDF with a veneer. Solid wood door construction is typically avoided because it can be subject to expansion and contraction with humidity changes. This can result in bowing and damaged painted or stained finishes.

What material is recommended for secure storage containers and cabinets?

Plywood cabinet or hardwood cabinet storage solutions are the best cabinet materials for securing containers.